Here is attempt #2 at dyeing wool roving in this particular colorway. I did kind of a no-no and changed two variables at once, But I'm pretty sure I still would've had to do #3 anyway, so no real time lost here.

After having so much dye left over

last time, I decided to try

not doubling the dye-to-fiber ratio for dye painting, as recommended in

Color in Spinning, and just go with the immersion dyeing ratios. I also changed my method of applying heat for setting the dye. In the first experiment I used the steamer technique, where you wrap your dyed roving up in a long piece of plastic wrap, then roll that "snake" up into a "snail" and place it in a steamer basket in a pot on the stove with water, and steam it for an hour at about 180F. The tricky part here is trying to maintain the temperature. If it goes much above 190F you can damage your fiber, and although the dye is supposed to start setting at 150F, it seems to take forever, and it's difficult to gauge the timing, so I try not to let it get below 175F.

I'd seen references to people setting dye in the oven instead, so I decided to try that in hopes that it would be easier to maintain a consistent temperature. Several people had said they had good luck with an oven temp of 250F for about an hour, so that's what I tried. What I

should have done was stick my thermometer in the fiber to make sure it was getting hot enough. I was lazy, and decided to "follow the recipe." I still had my roving wrapped in plastic wrap, then I placed it in a plastic bag before putting it in a baking dish because I didn't have a pan I wanted to dedicate to dyeing. It was impossible to tell whether the dye had exhausted without poking holes in the plastic, which of course would result in the dye leaking out. When I rinsed the roving I found that indeed, much of the dye had not set, and while I was getting the charcoal grey that I was looking for, the blue and the blue-green were much more muted than I'd intended.

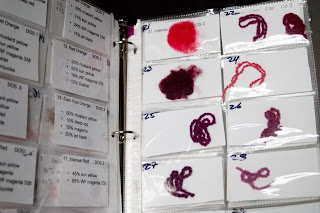

Here's the resultant yarn. Again, very pretty, but still not what I had visualized. I knew why I hadn't achieved the saturation in the colors that I wanted (the dye had not exhausted), but I was also disappointed that there still didn't seem to be enough distinction between the blue and the blue-green. They were still blending too much in the roving.

In doing a little deeper research, I found that people who oven-dyed for their business tended to use oven temps closer to 300-350F. Also, a lot of them were dispensing with plastic wrap entirely and laying their roving out in a zig-zag in a roasting pan, applying the dye, then covering the pan with tin-foil before putting it in the oven. For my third attempt, I went and got a cheap aluminum roasting pan. When I applied my dyes, this time I made sure that the blue and the blue-green were never adjacent to each other, always having the grey between them. I used my thermometer (the one I have has a cable that plugs into a temp readout, so I can shut it into the oven and monitor the temp from outside), and set the oven temp at 300F. I still had to do a lot of tweaking with the temperature (turning the oven up and down, opening the oven door, etc), and left it in for a total of about an hour and a half.

Tah-dah!

This is what I was aiming for! All the dyes exhausted, the grey has not turned black, and the blue and blue-green have not blended together - you can see that there are two distinct colors in this roving! The roasting pan technique also took up a lot less space on my tiny counter, which, with my clumsy self, is a definite advantage! I can see being able to fit probably two rovings per roasting pan of this size, and I should be able to fit four pans in the oven at once. Eight at a time is not bad!

Here is the yarn from this last roving. Still fairly subtle, still some blending in the yarn, but that's OK because that's where I want the blending to occur. But you can see three distinct colors, not just blue and grey like the second yarn, or blue and black like the first. It's all about control, and being able to get the results you were expecting. I'm sure I will still get lots of unexpected results, but at least now I seem to have the biggest variables (more-or-less) under control. Now I can start thinking up some different colorways! I'm really glad this only took three tries - I was going to get really tired of this color combo if I didn't figure things out!

I choose colors that I know will create something reasonably attractive in the finished product, and instead of mixing all of the colors of dye together for one solid color I sprinkle them randomly over the surface of the wool so that individual colors stand out and combine in different ways. If I want more dye penetration and less white space, I add more water to the crockpot.

I choose colors that I know will create something reasonably attractive in the finished product, and instead of mixing all of the colors of dye together for one solid color I sprinkle them randomly over the surface of the wool so that individual colors stand out and combine in different ways. If I want more dye penetration and less white space, I add more water to the crockpot. Yarn that is spun from tops dyed with this random crockpot dyeing method still have some variation in color, but the transitions between colors are much smoother and more gradual with little to no striping.

Yarn that is spun from tops dyed with this random crockpot dyeing method still have some variation in color, but the transitions between colors are much smoother and more gradual with little to no striping.